This article appeared first in the November Issue of Muzzle Blasts Magazine in 1990. NMLRA Members can read this and every other article ever published. Sign up today

During the past two years I have had the opportunity to measure the ignition time on a number of different flintlocks. The locks varied from superb original locks to modern day reproduction locks. Some were in mint condition, while others were somewhat used.

The equipment that I use to time locks consists of a computer and interface made to scientifically measure time in a high school or college physics lab. It has the ability to measure times to the nearest ten thousandths of a second. The lock is fired electrically, and time is measured until a flash in the pan triggers a photoelectric cell, stopping the clock.

The time taken by the computer interface is monitored and deducted from the lock time. The system seems to work well, and I have confidence in it.

The Manton and Durs Egg flintlocks, made by L & R Lock Company, were used for this article, the first of a series of articles dealing with the timing of locks in current production. I received the Manton in the mail and the Durs Egg at Friendship. To my knowledge, neither lock received any special treatment beyond normal care during production.

The locks were primed with FFFFG powder, measured with a small dipper. The flint and frizzen were cleaned after each firing. Each series of 20 trials was begun with a new flint. Flints were knapped when they became dull during the test.

A series of 20 trials on both locks was done with the flint bevel up and again with the bevel down. I felt that most locks work better one way than the other, and I needed to report both ways. The following chart contains the results:

Chart of times recorded

I found myself liking both of these locks. With flints installed to their best advantage, they worked very well. Neither lock seemed to be hard on flints. Little knapping was required while running the tests.

The Durs Egg lock showed a preference for flints installed bevel down (up side down to most of us). Its best average was obtained in this way. Its variation was twice as small with the bevel down. Also, the standard deviation with the bevel down was half that when the bevel was up. If I were shooting a rifle with this lock, I would place the flint bevel down.

The Manton lock had a different preference in flint installation. It performed best with the flint bevel up (right side up). However it worked quite consistently with the bevel down too. Its variation shows that it was quite uniform in its operation. I would probably shoot the Manton bevel up, but would not be at a disadvantage if the bevel were down.

I think it’s interesting to note that the best average from each of the locks were only .0010 seconds apart. This is, of course, impossible to detect with human senses. In fact, after watching probably more than 800 trials with different locks, I cannot tell the difference between a normal time (.0390) and one twice as large (.0780). In order for me to visually detect a slow time, it has to be over .1000 seconds.

The point of all this is that if a shooter analyses a shot and thinks to himself, “That sure was slow”, it must have been VERY slow, probably three or four times as slow as usual. Anything less than this, the shooter would not have noticed. It is also possible that a slow shot was not caused by the lock at all. I am convinced that problems with touch holes cause more “slow” shots than poor lock ignition.

I believe that there is much to be learned about lock timing. This article just scratches the surface. In future articles I would like to study and time other locks currently available to shooters. I would be interested in ideas or study methods that others might have to extend what we know about lock ignition.

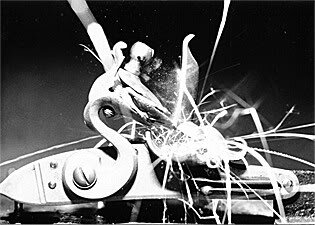

Photo #1

Shown .011 seconds after firing, the flint has just struck the frizzen. Notice the flint chips spraying off the contact area.

Photo #2

At .013 seconds the flint is nearing the bottom of the frizzen. Flint chips are still flying. Top jaw screw shadow shows where the parts will be when the lock is at rest.

Photo #3

At .015 seconds, the flint movement is almost finished. However, the frizzen has considerable travel left.

(Standard Deviation insert)

Standard deviation is a measure of consistency of the statistics. High standard deviations indicate large deviations from the average. The more uniform the trials are, the lower the standard deviation should be. Sixty-six percent of the times should fall within one standard deviation from the average.

(Photo explanation)

The photos were taken with the shutter open in a dark room. The computer fired the lock, caused a measured delay, and then fired the electronic flash. A faint shadow can be seen where the parts come to rest (top jaw screw and frizzen). The sparks are illuminated not by the flash but by their own light. They were not formed at the time the flash was fired. They show because the shutter remained open after the flash ended.